The structural design of Rexmove's Chain Conveyor Machine focuses on stability, durability and precision, which is the fundamental guarantee for its excellent performance in various industrial scenarios. Media structura et commoda materialia sunt haec:

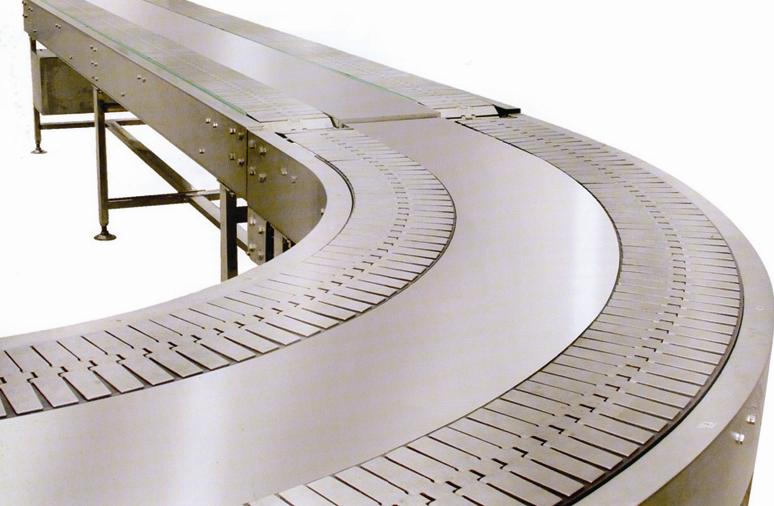

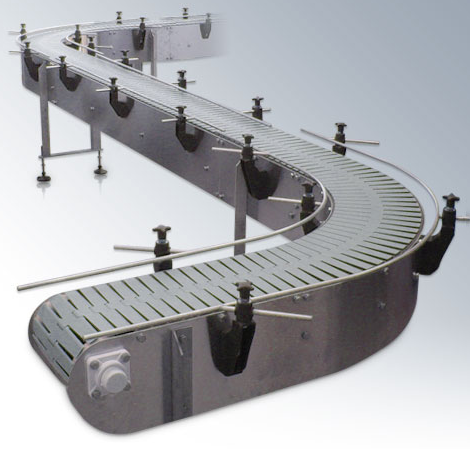

- Scientific Structural Design: The conveyor adopts independent chain plates connected in series by high-strength pins to form a continuous conveying surface. This modular structural design not only ensures the flatness and stability of the conveying surface but also enables flexible combination and extension according to different production site layouts and process requirements. Whether it is horizontal conveying, inclined conveying or corner conveying, it can be perfectly adapted, and the connection between equipment is smooth, avoiding material jamming during the conveying process. At the same time, the reasonable spacing between chain plates and the optimized pin connection structure ensure the stability of the conveyor during high-speed operation and improve the overall conveying precision.

High-Quality Material Selection: The chain plates are available in two high-performance material options: steel and engineering plastics, to meet the needs of different industries and working conditions. Laminae chalybeae catenae altae-qualitatis incorruptae chalybis vel carbonis factae sunt, quae habent praestantem onus-portantes facultatem et impulsum resistentiae, et aptae sunt ad grave-officium missionem ferendis ut magnae sarcinae et materiae mole. Engineering plastic chain plates (mainly POM, PP and other materials) are lightweight, corrosion-resistant, wear-resistant and easy to clean, which fully meet the strict hygiene requirements of food, pharmaceutical and cosmetics industries. Both material types have been subjected to strict wear resistance and fatigue resistance tests, ensuring long service life even in long-term continuous operation.Catena Regismovetur Machina Conveyor amplam recognitionem a clientibus globalis consecutus est propter commoda comprehensiva eius effectionis, quae specie in sequentibus aspectibus reflectuntur:- Strong Load-Bearing Capacity: Thanks to the scientific structural design and high-quality material selection, the conveyor has excellent load-bearing performance. The steel chain plate version can easily bear heavy loads of tens to hundreds of kilograms, which is suitable for conveying large and heavy items such as cartons and cans. The engineering plastic chain plate version also has good load-bearing capacity for light and medium loads, meeting the conveying needs of most daily chemical and food products. Firmum onus baiulans facultatem efficit ut TRADUCTOR sine deformatione vel defectu diu stabiliter operari possit.

Robust & Stable Structure: The integral frame of the conveyor is made of reinforced steel or aluminum alloy, which has high structural strength and rigidity, and can resist the impact and vibration generated during the conveying process. The precise fit between the chain plates and the stable operation of the drive system (equipped with high-quality gear motors) ensure that the conveyor runs smoothly with low noise and no obvious vibration, effectively reducing the damage to conveyed materials and improving the stability of the production line.

High Conveying Precision: The independent chain plates are precisely processed and connected by high-precision pins, which ensures the flatness and consistency of the conveying surface. The conveyor can achieve precise speed regulation through the frequency converter, with a conveying speed adjustable according to actual needs, ensuring that the materials are conveyed at a stable speed and accurate position. This high conveying precision is particularly important for the connection of post-packaging links, such as automatic labeling, capping and case packing, ensuring the smooth progress of the entire production line.

Post time: 2026-02-03 14:56:17